Concise Report

Kinetics of Catalyzed Thermal Degradation of Polylactide and Its Application as Sacrificial Templates

Li Feng, Chenhui Cui, Zhen Li, Mengyuan Zhang, Shenghui Gao, Qiang Zhang, Youshen Wu, Zhishen Ge, Yilong Cheng, and Yanfeng Zhang*

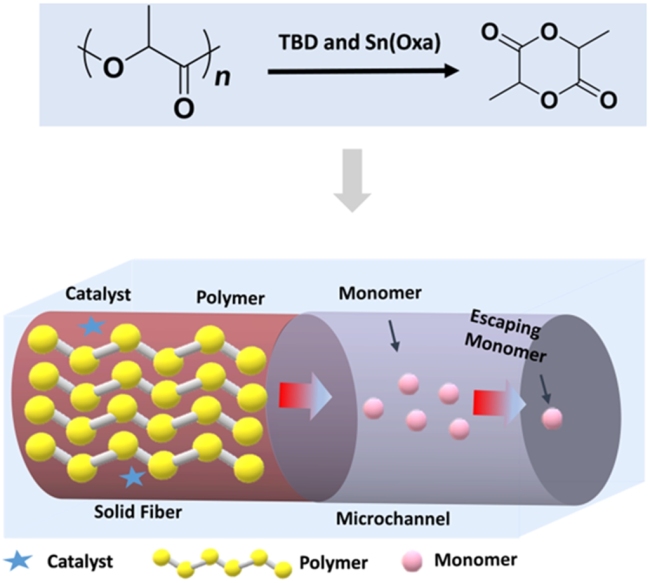

Polylactide (PLA) is an outstanding sacrificial template material for the manufacture of microchannels in a thermosetting matrix. However, the initial thermal degradation temperature of pure PLA is relatively high (about 280 °C), which limits its use as a sacrificial template. In this report, we found that TBD, an organic base catalyst, can significantly reduce the thermal degradation temperature of PLA. TBD has higher catalytic activity for the thermal degradation of PLA compared with Tin(II) oxalate (Sn(Oxa)), one catalyst reported in the literature. Moreover, the gaseous products catalyzed by TBD for PLA thermal degradation are mainly lactide, and the formation temperature of the monomer is lower and the yield is higher, which may have potential value for PLA recycling. A combined catalyst, S8T2, was composed of 80% low activity catalyst Sn(Oxa) and 20% high activity catalyst TBD, which can catalyze the rapid degradation of PLA without greatly damaging the mechanical properties of PLA. PLA-S8T2 sacrificial fibers can form high-precision one-dimensional microchannels in the epoxy resin matrix, and 3D-printed PLA-S8T2 sacrificial templates can be used to form three-dimensional microchannels in a thermosetting matrix by vaporization of sacrificial components process (VaSC). These features highlight the great potential of PLA-S8T2 as sacrificial template material for the preparation of the complicated microchannels in the thermosetting matrix.

Polymers | Gaseous product | Kinetics | Sacrificial template | Microchannel

聚乳酸的催化热降解动力学及其作为牺牲模板的应用

生命系统依靠遍布全身的血管网络来实现软组织和硬组织中的例如运输、交换以及排废等多种生理功能。相比之下,人工合成的复合材料具有较高的强度重量比,但由于缺乏类似天然材料的微通道结构,导致其难以应用于如微流控反应器、微脉管自愈合等具有巨大发展潜力的领域。因此,发展一种与当前复合材料制造工艺完全兼容的方法以在复合材料中制造微通道网络仍然是一个亟需解决的挑战。

通过将牺牲纤维嵌入热固性聚合物基体中,再于真空中加热降解以形成中空通道的牺牲组分汽化法(VaSC)受到了广泛关注。聚乳酸(PLA)因其可降解且降解产物无污染被认为是一种理想的牺牲纤维,然而由于其热降解温度过高(约280 oC)限制了它的应用。研究发现,催化剂的加入可使PLA的降解温度降低,这些催化剂主要包括特定的金属(Polymer 2004, 45, 1197-1205.)、碱金属氧化物(ACS Appl. Mater . Interfaces 2012, 4, 503-509.)、含锡化合物(Adv. Funct. Mater. 2015, 25, 1043-1052.)。然而,这些催化剂的催化效率有限,无法实现PLA在更温和条件下的降解。因此,需要开发更高效的催化剂以降低牺牲模板热消除过程中对热固性基体的热损伤。

最近,西安交通大学化学学院张彦峰教授团队发现有机强碱1,5,7-三叠氮双环(4.4.0)癸-5-烯(TBD)能够高效催化PLA热降解。在较低的温度(175oC)下,TBD作为一种亲核试剂能够快速进攻PLA中的羰基碳并形成Acyl-TBD键,Acyl-TBD易猝灭并释放PLA链段,在此过程中形成的氧阴离子进攻链段上的羰基碳,并最终释放气态单体丙交酯。与金属催化剂草酸亚锡相比,TBD催化PLA热降解的温度低、时间短、速率快。此外,TBD可以在催化温度下分解而不会导致催化剂残留。通过将高效催化剂TBD和其他催化剂按照不同比例混合,可以实现PLA机械性能和降解速率的可控调节。嵌入在复合材料中的含有2wt%(相对于PLA的质量)复配催化剂S8T2(80%Sn(Oxa)和20%TBD)的牺牲纤维PLA-S8T2在200oC下仅需4h即可完全降解形成高精度的微通道。这一高效催化剂的开发工作为复合材料中微通道的构建提供了可靠依据。